Rapid Pulsed Light Sintering of Silver Nanowires on Woven Polyester for Personal Thermal Management with Enhanced Performance, Durability, and Cost-Effectiveness

- Journal

- Scientific Reports

- Vol

- 8

- Page

- 17159

- Year

- 2018

- File

- 2018_Sci. Rep._8_17159.pdf (4.0M) 4회 다운로드 DATE : 2022-03-07 11:23:53

- Link

- https://www.nature.com/articles/s41598-018-35650-7 1754회 연결

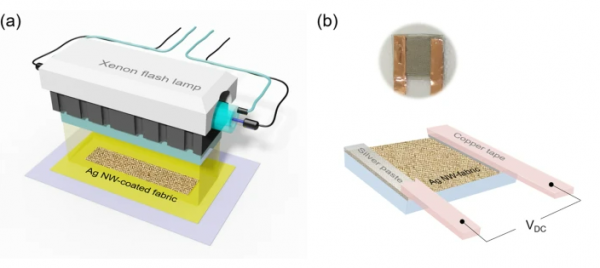

Fabric-based personal heating patches have small geometric profiles and can be attached to selected areas of garments for personal thermal management to enable significant energy savings in built environments. Scalable fabrication of such patches with high thermal performance at low applied voltage, high durability and low materials cost is critical to the widespread implementation of these energy savings. This work investigates a scalable Intense Pulsed Light (IPL) sintering process for fabricating silver nanowire on woven polyester heating patches. Just 300 microseconds of IPL sintering results in 30% lesser electrical resistance, 70% higher thermal performance, greater durability (under bending up to 2 mm radius of curvature, washing, humidity and high temperature), with only 50% the added nanowire mass compared to state-of-the-art. Computational modeling combining electromagnetic and thermal simulations is performed to uncover the nanoscale temperature gradients during IPL sintering, and the underlying reason for greater durability of the nanowire-fabric after sintering. This large-area, high speed, and ambient-condition IPL sintering process represents an attractive strategy for scalably fabricating personal heating fabric-patches with greater thermal performance, higher durability and reduced costs.