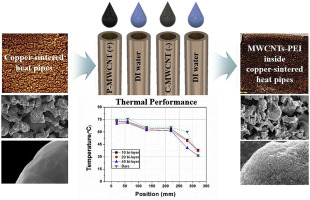

Layer-by-Layer Assembled Carbon Nanotube Polyethyleneimine Coating Inside Copper-Sintered Heat Pipes for Enhanced Thermal Performance

- Journal

- Carbon

- Vol

- 140

- Page

- 521

- Year

- 2018

- File

- 2018_Carbon.pdf (3.4M) 4회 다운로드 DATE : 2022-03-07 11:19:59

Biporous structures at the nano–microscale are promising candidates for controlling phase change heat transfer, through their enhanced capillary wicking and fluid transportation. However, existing methods for fabricating biporous structures involve complex process which is not suitable for small-scale thermal devices such as heat pipes, owing to their confined and non-flat inner structures. Herein, we report the biporous structures inside copper-sintered heat pipes, enabled by layer-by-layer (LbL) assembled multi-walled carbon nanotube (MWCNT)-polyethyleneimine (PEI) coating for enhanced thermal performance. The repetitive filling and removing of the oppositely charged solutions with MWCNT-PEI and carboxylic-functionalized MWCNTs assembled the nanoporous MWCNT-PEI coatings (10, 20, and 40 bilayers) on the microporous copper-sintered inner surfaces. The fiber-like MWCNT networks structurally manipulated morphology and thickness of biporous structures, while the hydrophilic PEI shells chemically optimized wettability. A reduced thermal resistance (∼14.3%) was observed for MWCNT-PEI coating in 10 bilayers, due to the enhanced capillary wicking, interfacial contact areas, and bubble dynamics, whereas the 40 bilayers did not exhibit improved thermal performance owing to the redundant nanoporous layers causing reduced volume of microporous structures and increased thermal resistance. The LbL-assembled MWCNT-PEI coatings would act as functional layers to improve the performance of miniaturized and thin-film-based thermal devices.